Not really a repair, but possibly useful info for somebody and an excuse to share some love for the SC-CH900, for me the best, the pinnacle of the mini hifi system in the 90's. Im sure a sony MHC-6600 fan would disagree :-)

So the Technics SC-CH900, I lusted after this baby for 23 years ! I always had a fascination and interest in home electronics, hi fi's TV's etc so back in 1991 after I started work I set about saving for and buying my first stereo. I knew all about HiFi, what cable to buy etc but despite it not being 'HiFi' in the seperates and OFC speaker cable sense I was hooked on getting one of these. I think it was the copious use of VFD displays that did it. So every week I would check out the stereos in the local shopping precinct, It was between the Technics and a Sony MHC3600/5600/6600. So the time came to buy, what I actually bought was a SC-CH700, largely the same system but without Dolby surround capability or the brushed metal finish. Crucially though it was from memory about £200-£300 less than the £1000 of the 900, a lot of money for me in 1992. The CH700 did me many years of good service and I loved it but I always regretted not getting the top of the tree 900. So good old eBay delivered the goods and all these years later I have a pristine SC-CH900 and I love it.

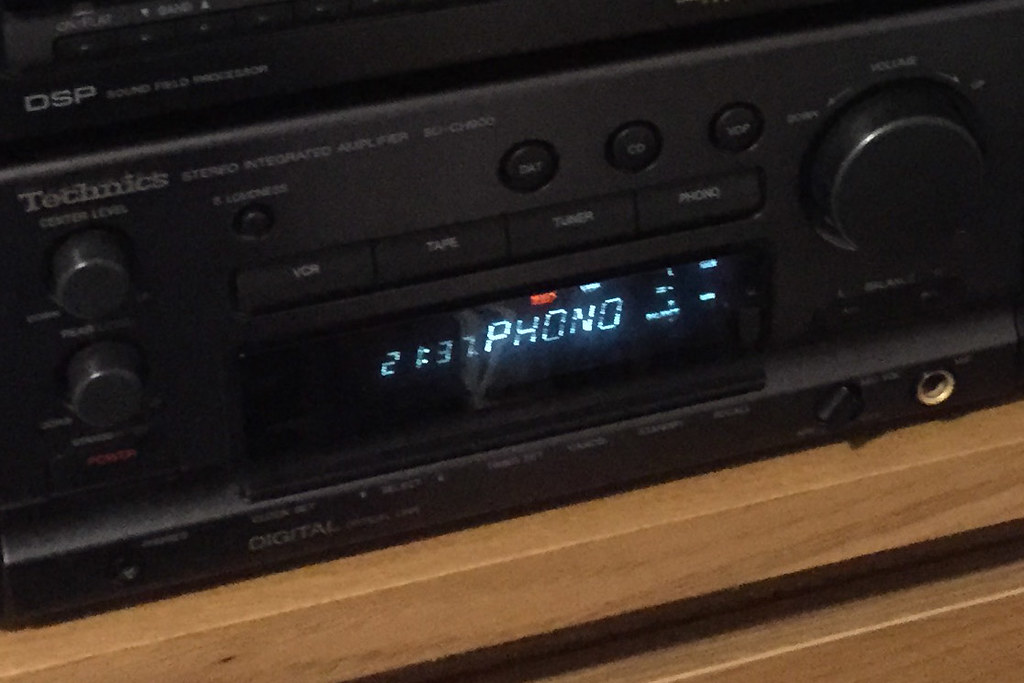

The only issue with it was the display of the main amp unit, the other components looked as new but the amp had 2 issues, the cover / filter over the VFD was cloudy / hazy / dirty. Secondly some parts of the display were significantly brighter than other, some looked over bright, others too dim ? As seen in the picture below from just after I bought it.

I looked into getting a new display and considered swapping the display from my 700. Panasonic UK said that they did not support the unit anymore but armed with a part number from the service manual I inquired in the US and found it was still available, would have cost about £40.

I did a bit googling on VFD's and found some referance to the grid wires oxidising due to lack of use. Either manually powering them and flowing a bit more than normal current through them may help or just leaving the unit in for an extended length of time. Although the clock is lit all the time it didnt seem to be getting any better after a week in standby so I left it fully powered on overnight. Success, the next day the display was bright and uniform.

So I then stripped the unit down to clean the inside of the display, as the amp is on all the time in standby and has a fan running when the volume is turned up I suspect that is why it had got dirty and the other components looked like new.

I wasn't dissapointed with the construction, the service manuals are amazing in quality and the unit was too. It came apart very nicely, lots of screws, no forcing or plastic tabs breaking.

A careful gentle wipe and it was like new again.

All set up with my SL1210 MK3D. A video of it in action.

http://youtu.be/_xItB0q_CI0

I knew I had the brochure sat in my loft somewhere so dug it out and scanned it below, ah the memories.

A link to the whole brochure I scanned in.

https://www.flickr.com/photos/120943638@N03/sets/72157649178929430/

The only other issues I have come across with these systems relates to the fan, when the volume goes above a certain level an internal fan kicks in, if this fails the unit shuts down. My SC-CH700 did this and I fitted a new, quiter fan. The 900 seems ok so far (and I am actually just useing hte the whole thing as a pre amp currently).

The fan was my only gripe with the 700 as I found it intrusive the way it would come in and out, almost with the beat at the volume levels I listened to the unit at.

+edit.png)